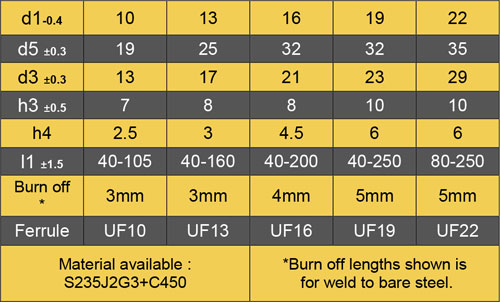

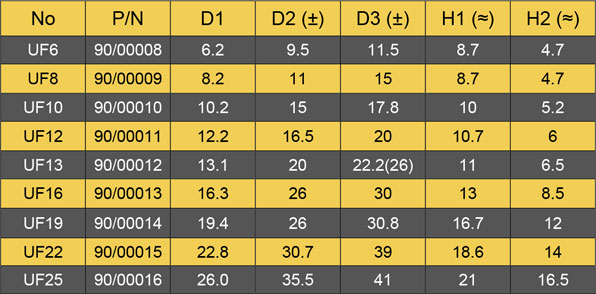

Technical Specs of Ceramic

Ceramic role in the Stud Welding Process :

According to the standards provisions, articles published by the prestigious scientific references and documents provided by leading companies and founder of the process (NELSON), ferrule ceramic is as a main element affecting the welding process.

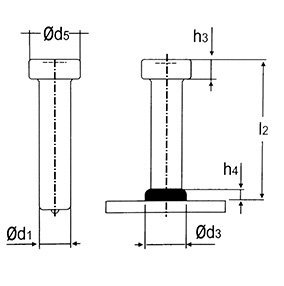

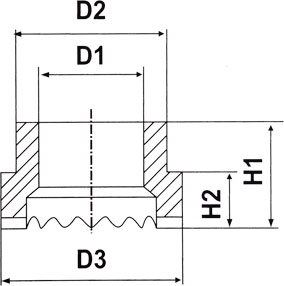

These ceramics from the physical dimensions, design, geometry and type of material standpoint are as a principal and affective factor in quality of welding. They are designed in such a way to have the following functions:

1. Forming molten pool and surrounding the melt.

2. As a mold to form the melt during solidification.

3. Creating a uniform/homogenous welding muscle

4. Control welding atmosphere and its surrounding.

5. Protect electric arc area and electrical radiation during sparks.

![]()

![]()

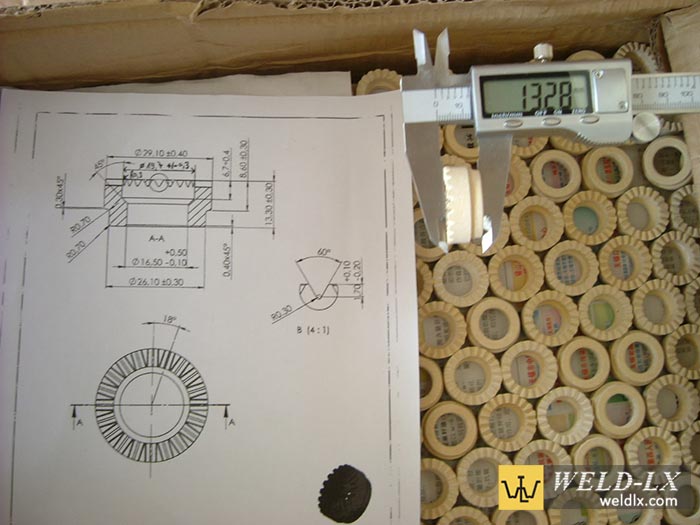

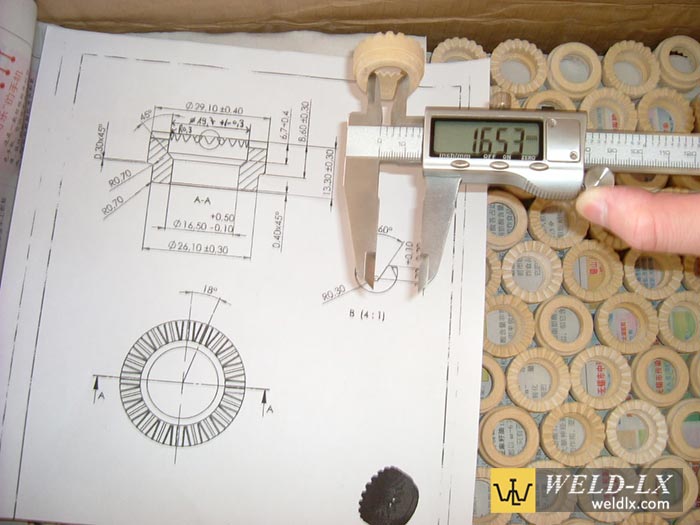

Ceramic Tests, loading and shipment steps which has been performed by international inspection company